Oct. 07, 2024

As the demand for different easy-to-open packaged products such as packaged food and canned beverages increases, the need for a more efficient method of packaging to meet this demand is also increasing. This includes the use of automatic can seaming machine to produce tamper-evident seals to ensure the safety of the consumers. Thus, automatic can seaming machine manufacturers also need to innovate their products to keep up with this demand.

However, choosing a suitable automatic can seaming machine for a certain application can be challenging as different tin/can sealer is needed for handling different types of products. Especially if you are new to the industry and know nothing about these automatic can seaming machine. If you are having the same problems, then you are in the right place! In this article, we will help you familiarize yourself first with the basic principles of the automatic can seaming machine before you start purchasing one.

What is a Automatic Can Seaming Machine?

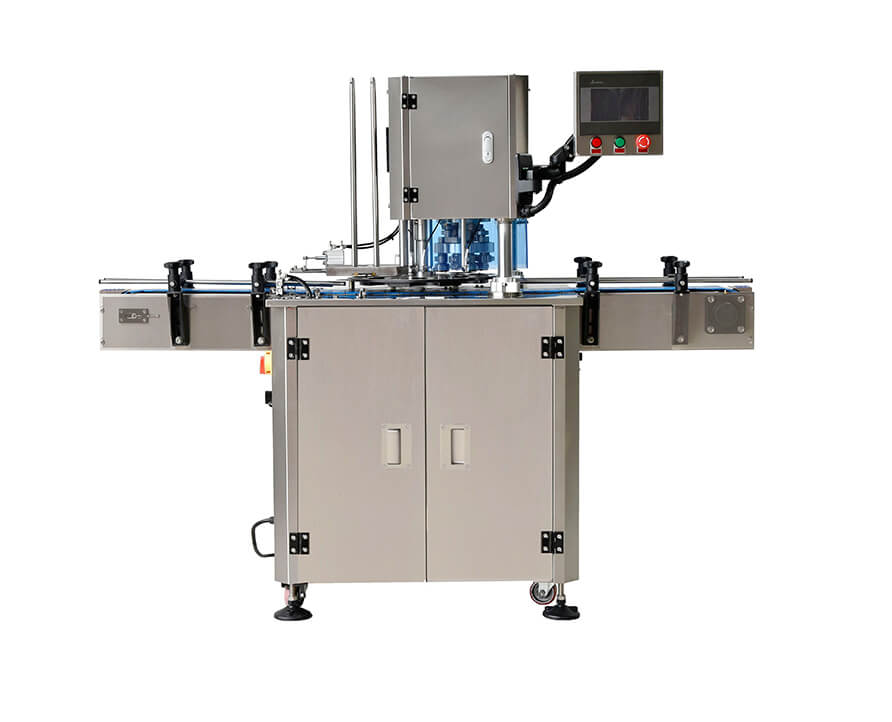

An automatic can seaming machine is used to hermetically seal a lid to a can body during the packaging process using a double, or sometimes triple, seam. The lid is usually made from tin-plated steel. Meanwhile, the can’s body can be made of paper (like whiskey cans), tin, aluminum, PET, plastic, or glass. The formed seam is usually leak-proof. However, this still depends on the type of products being packaged.

The automatic can seaming machine can either have one or more seaming heads in which each head is considered as a separate machine. The most popular machines have 4, 6, or 12 heads with the number of heads increasing with the machine’s speed for production lines requiring higher demands. Moreover, you can automate can sealer to streamline the packaging process to improve production efficiency and save on labor costs. Apart from these, you can also enjoy other benefits of integrating an automated packaging machine in your production line.

Different types of Automatic Can Seaming Machine

Automatic can seaming machine will not need that much interaction with the operator during the sealing process because the majority of the processes are done automatically. The operator only needs to supply lids in bulk to the machine. Thus, these machines are recommended for businesses requiring high production demands.

For semi-automatic can sealing machine, the operator needs to initiate the can seaming process usually through a finger or footswitch for each sealing cycle. These machines typically seal one container at a time so they are recommended for small productions or home use.

Rotary can seamer machine perform the sealing operation while the containers rotate on their axis. Fully automatic can seaming machine will usually have these types of designs allowing them to seal containers at fast speeds. Thus, making them ideal for industries with big operations.

Also, rotary can sealing machine are often used for seaming round cans and are equipped with up to 18 seaming heads revolving around a single head.

On the other hand, non-rotary can seamer machine allow the cans to remain stationary through the seaming process. This avoids damage to the cans being sealed and the products contained inside. Thus, making them ideal for dealing with liquid products packaging as they prevent spilling.

While rotary can sealing machine are mostly used for round cans, non-rotary ones are used for other shapes like oval, oblong, and rectangular cans. Also, most semi-automatic can seamer machine have non-rotary machine designs.

Conclusion

Being knowledgeable on any type of machine you are purchasing always helps in guaranteeing that you get the ideal machine for your application. It also ensures that you will have a problem-free production line. It does not only lower the chances of errors but also decreases operation costs which help you generate promising revenues that will benefit your business in the long run.

Guangzhou Full Harvest Industries Co., Ltd., a bespoke can sealing machine manufacturer in China including can seamer machine, nitrogen tin can sealer, can sealing machine, automatic can seaming machine, can closer machine, tape around sealing machine, can sealer, automatic glass jar vacuum capping machine, can flanger machine, can seamer and box taping machine, does not only make sure that you get solutions perfectly tailored to your needs, but also ensures that you’ll have durable and high-performance machines thoroughly crafted. Contact us now for a perfect packaging solution!

No.222 Nancun Team , Lingnan Village , Aotou town Conghua District of Guangzhou , China

+86 20 3751 0321

FOLLOW US

Tel/ Fax: +86 20 3751 0321

E-mail: sales@gzfharvest.com

Add: No.222 Nancun Team , Lingnan Village , Aotou town Conghua District of Guangzhou , China